LCD Display

Embossing Process

Precision Coating

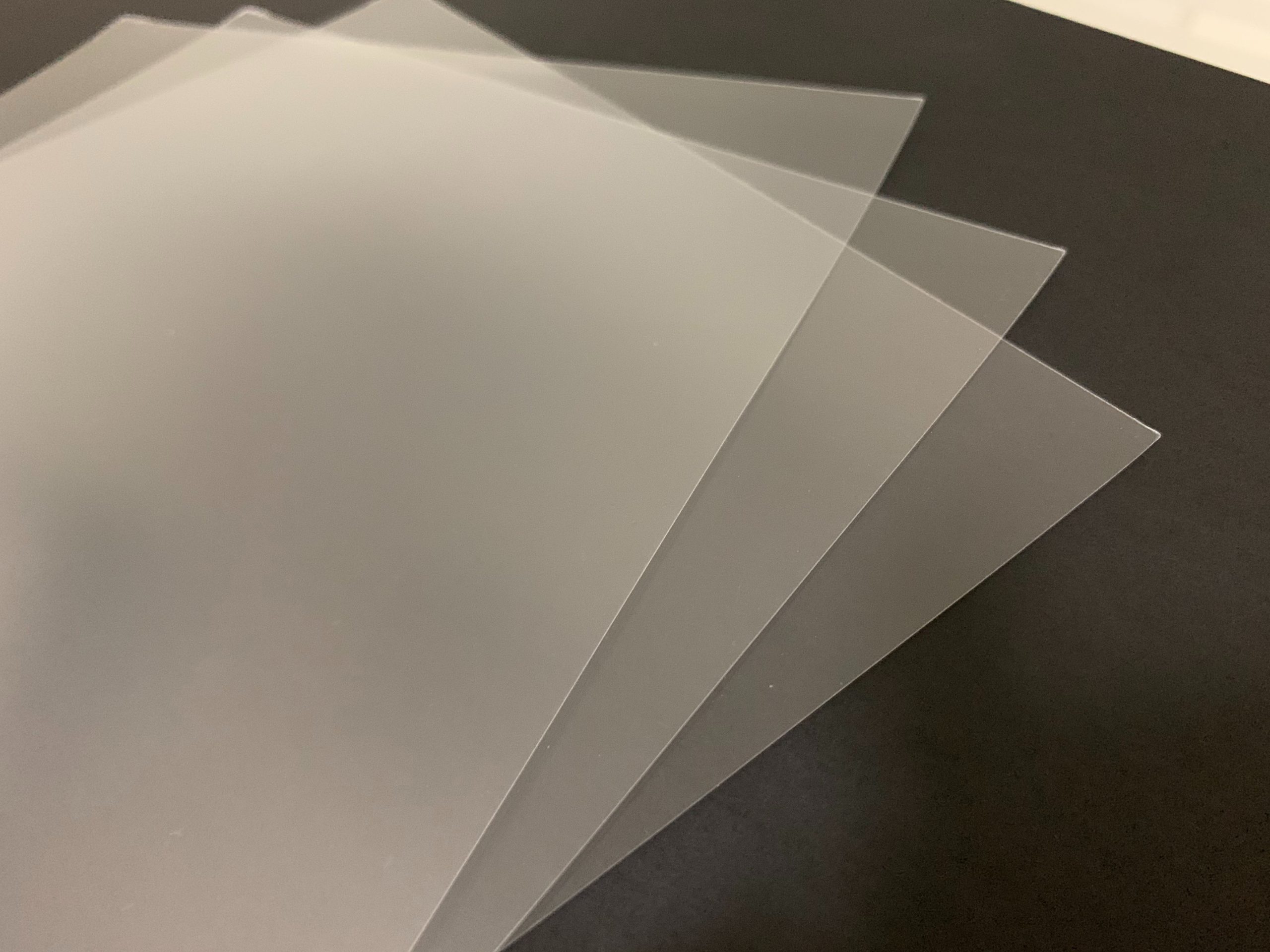

Polarizer Protection Film

High cleanliness PET protective film, suitable for all kinds of polarizer manufacturing process and shipping use, non-toxic, non-polluting substances for rapid use, in line with environmental requirements.

Application

Polarizer manufacturing process

Polarizer shipping

Small to large size displays

Features

- Anti-static

- High cleanliness

- Non-polluting

- Non-toxic

Product Specification

| Type | Thickness (Base Film / Coating Layer/Release Liner) | % Transmittance | Peel Adhesion | Surface Resistance(Coating Layer) | Surface Resistance(Base Film) |

|---|---|---|---|---|---|

| PP6 | 38/15/19 | >88% | 8±3g | <1*10¹²Ω/口 | <1*10¹¹Ω/口 |

TAC Anti-glare film

A hard coat and anti-glare layer is applied to a triacetate cellulose base film to produce a surface treatment for polarizers.

Application

Small to large size displays

Features

- Anti-scratch

- Hard coat

- Anti-glare

Product Specification

| Type | Thickness (Base Film/Coating) | % Transmittance | % Haze | Hardness | Abrasion Resistance Test |

|---|---|---|---|---|---|

| TG1 | 60/5 | >90% | <3% | 2H | 500g |

| TG3 | 60/5 | >90% | 3±1% | 2H | 500g |

| TG25 | 80/5 | >90% | 25±2% | 2H | 500g |