Touch Panel

Embossing Process

Precision Coating

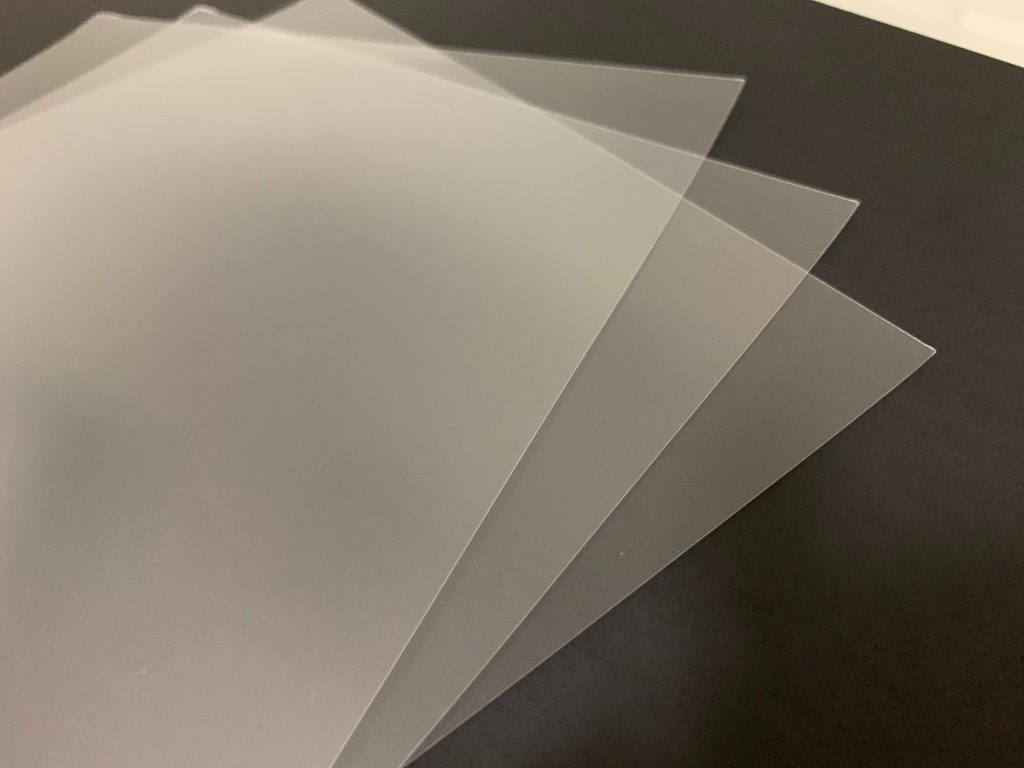

Anti-Static Protection Film

High cleanliness PET protective film, suitable for all kinds of polarizer manufacturing process and shipping use, non-toxic, non-polluting substances for rapid use, in line with environmental requirements.

Application

Touch panel

Car

Cover

Features

- Anti-static

- Anti-blocking

Product Specification

| Type | Thickness (Base Film/Coating Layer/Release Liner) | % Transmittance | Peel Adhesion | Surface Resistance(Coating Layer) | Surface Resistance(Base Film) |

|---|---|---|---|---|---|

| PPA | 38/18/25 | >86% | 6±3g | <1*10¹²Ω/口 | <1*10¹²Ω/口 |

In Process Panel Protection Film

In process panel protection film has low silvering and re-working characteristics. It is suitable for the process and shipment of panels, ITO and glass covers, and has low pollution and high stability. Maintains product characteristics during the process.

Application

Small to large size displays

Features

• Anti-static

• Re-working

Product Specification

| Type | Thickness(Base Film/Adhesive Layer/Release Liner) | %Transmittance | Adhesive Force | Surface Resistance (Coating Layer) |

|---|---|---|---|---|

| PPK | 50/10/50 | >86% | <3g | <1*10¹²Ω/口 |

| PPG | 50/10/50 | >86% | <3g | <1*10¹²Ω/口 |

| PPL | 50/10/50 | >86% | <3g | <1*10¹²Ω/口 |

| PPG | 100/10/50 | >86% | <3g | <1*10¹²Ω/口 |

Protection Film

The high temperature resistant protective film is suitable for ink printing, ITO film high temperature process protection, to avoid the material from being scratched in the high temperature process, and has good high temperature resistance characteristics. It can not be contaminated by residual glue and transfer in the 180 degree process.

Application

ITO process

High temp process

Features

- High temp resistance

Product Specification

| Type | Thickness(Base Film/Adhesive Layer/Release Liner) | %Transmittanc | Adhesive Force | Surface Resistance (Coating Layer) | (MD) | (TD) |

|---|---|---|---|---|---|---|

| PPU | 125/12/25 | >86% | 8±3g | <1*10¹²Ω/口 | <5% | <2% |

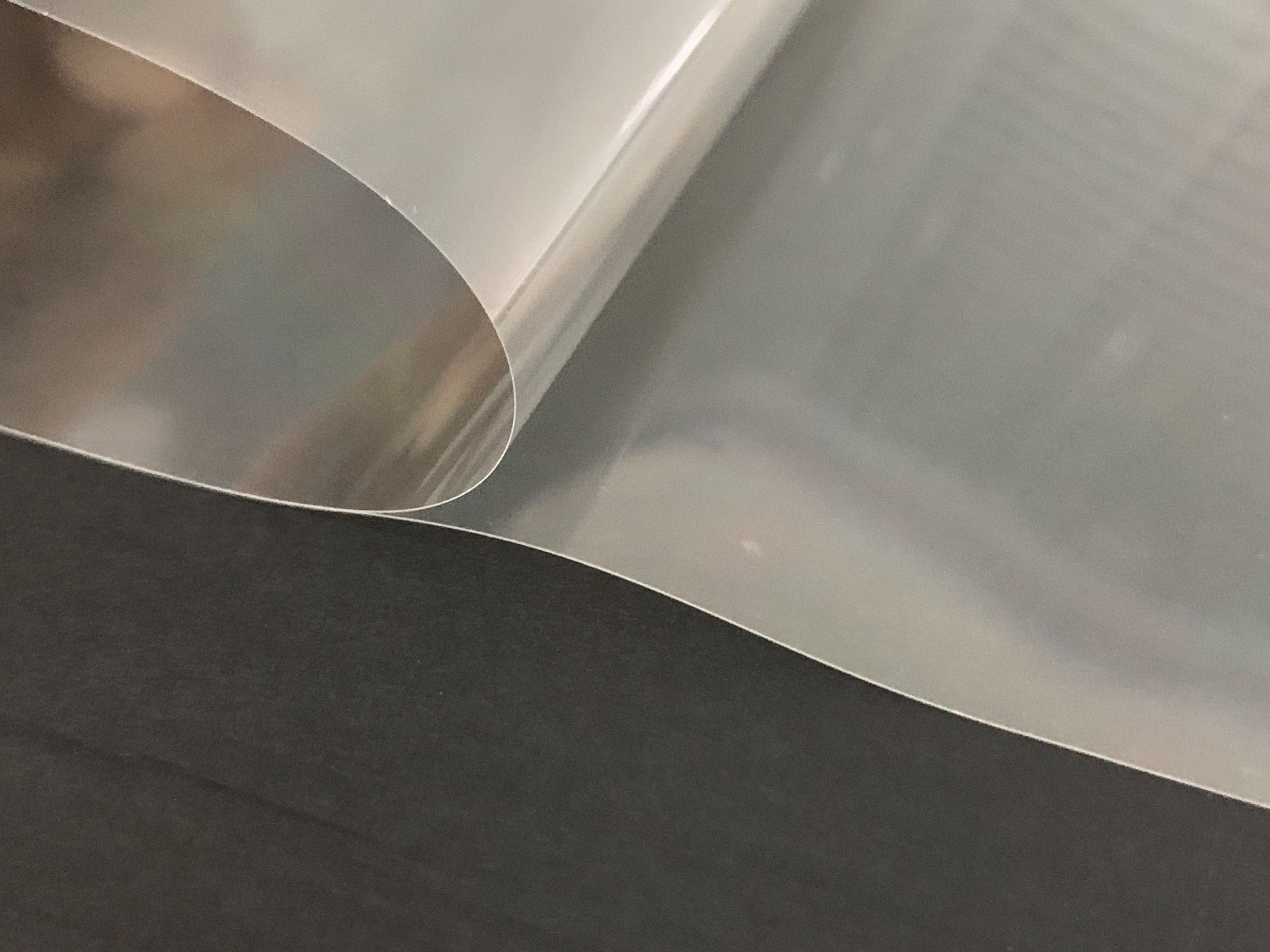

Hard Coat Film

PET double side hard coating film applied to ITO sputtering substrate, to increase anti abrasion strength of substrate surface during ITO sputtering process, also with anti-blocking treatment to increase yield rate.

Application

ITO film

Features

- Anti-scratch

- Hard coat

- Anti-blocking

Product Specification

| Type | Configuration(Hard coat /Substrate/Hard coat ) | T.T> | Haze | Hardness(HC side) | Hardness(AB HC side) | Abrasion Resistance Test |

|---|---|---|---|---|---|---|

| PM44D5XF | 5/125/5 | >90% | <3% | 3H | H | 750g |

| PM44K0U2 | 5/188/5 | >90% | <3% | 3H | H | 750g |

Masking Protection Film

Masking film for products that have an ink layer.

Application

Cover glass

Printing

Features

- Low pollution

- High stability

Product Specification

| Type | Thickness (Base Film / Coating Layer/Release Liner) | % Transmittance | Peel Adhesion | Surface Resistance(Coating Layer) |

|---|---|---|---|---|

| PCA | 50/16/50 | >86% | 8±3g | - |

| PPJ | 100/12/50 | >86% | 18±5g | <1*10¹²Ω/口 |

OCA Film(Optical Clear Adhesive Film)

Application

Small to large size displays

Features

• Excellent clarity and light transmission

• Acid free

• Corrosion free

• Anti-Newton ring

Product Specification

| Type | Configuration(Heavy release film/adhesive/Light release film) | Haze | Peel strength | L* | a* | b* |

|---|---|---|---|---|---|---|

| DA-7025 | 75/25/75 | <1% | >8N/25mm | 100 | 0 | 0 |

| DA-7050 | 75/50/75 | <1% | >10N/25mm | 100 | 0 | 0 |

| DA-7100 | 75/100/75 | <1% | >12N/25mm | 100 | 0 | 0 |

| DA-7125 | 75/100/75 | <1% | >12N/25mm | 100 | 0 | 0 |